Continuing on the path to a sustainable future remains a focal point for Essex Furukawa Magnet Wire. Our effort to refine green production includes achieving Zero Waste to Landfill across our magnet wire plants, metals processing facilities as well as chemical processing locations. It is also one of the key initiatives of the Vision 2030 plan that was set forth by CEO Brian Kim in April.

Over the course of the last several months Zero Waste to Landfill assessments were conducted at all Essex Furukawa locations, and the results were encouraging as three North American locations; all three European locations, as well as operations in China and Japan have been certified as Zero Waste to Landfill.

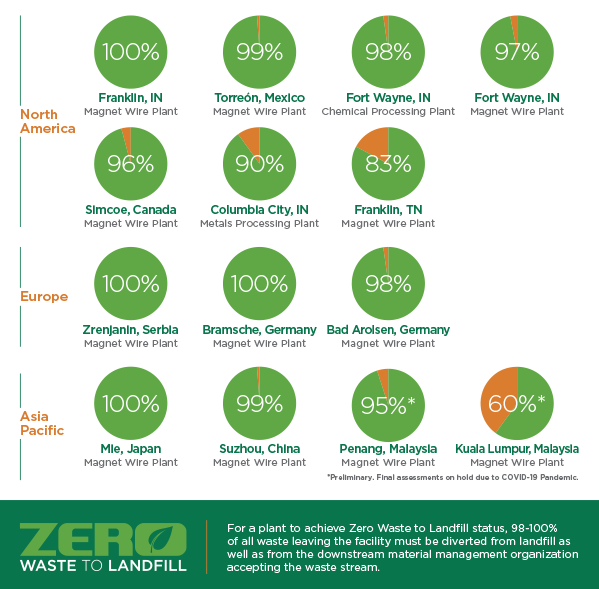

For a plant to achieve Zero Waste to Landfill status at least 98% of all waste leaving the facility must being diverted from landfill as well as from the downstream material management organization accepting the waste stream.

“Becoming Zero Waste to Landfill across all of our global locations was always viewed as an ambitious but achievable goal,” Austin Robinson, Sustainability Project Manager said. “When we began working with our business leaders and plant managers for this assessment it was an unknown where our baselines would be and what work would be needed to achieve Zero Waste to Landfill.

“We were thrilled when we learned that so many of our locations have been pushing towards this outcome and we are both excited and encouraged to have been able to identify areas for improvement.”

The assessments were completed by a sustainability consulting organization in a joint effort with Essex Furukawa, and the results were as follows:

In North America, three locations were able to be certified at Zero Waste to Landfill.

- Franklin (IN) Magnet Wire Plant already achieved 100% diversion rate . Meaning there is no waste remaining to be diverted.

- Torreón (Mexico) Magnet Wire Plant was rated at 99%, with multiple recommendations to close the loop on the remaining 1% that is going to landfill.

- The Chemical Processing Facility in Fort Wayne (IN) scored a 98% and is looking into converting 1.64% of the waste to energy at a nearby location.

Of the other plants in North America, two magnet wire plants – Fort Wayne (IN) and Simcoe (Canada) – both just missed the threshold with 97% and 96% diversion rates, respectively. Fort Wayne was discovered that its waste was oversight that can be accounted for by better plant management processes. Simcoe had 1% of waste being erroneously sent to landfill and can be recovered moving forward, with another 2% being identified as available for mitigation and reduction practices.

The Metals Processing Center located in Columbia City (IN) was rated at 90% with identified opportunity on 8% of trash. Lastly, the Franklin (TN) Magnet Wire plant was rated at just 83% on its Zero Waste to Landfill assessment. It was found that 14% of its plant waste is water waste, and there is currently a study being done to correct that waste stream.

In Europe, all three locations were certified as Zero Waste to Landfill.

- Zrenjanin (Serbia) and Bramsche (Germany) were determined to be at 100% diversion rate.

- Bad Arolsen (Germany) was 98%, with 1.47% waste being created by downstream waste management and could be improved upon to reach over 99%.

The Asia Pacific markets that were able to be analyzed both were determined to be Zero Waste to Landfill. Analysis on two plants in Malaysia have been delayed due to the impact of Covid-19.

- Mie (Japan) assessment was returned with 100% diversion rate.

- Suzhou (China) was analyzed to have 99% diversion. Almost the entirety of its 1% remaining was perishable waste and a recommendation to begin composting was made.

“Essex Furukawa has embraced a holistic approach to sustainability,” Kim said.

“We will be transparent about our progress towards Vision 2030, and that includes highlighting our successes as well as addressing where we can improve.

“We are proud of our locations that are already Zero Waste to Landfill, and we are prepared to take the next steps for those locations that are not currently at the necessary diversion rates.”