“Let us do it. Let us do it in Fort Wayne.”

It may seem like a simple philosophy—Let us do it here—however Fort Wayne, Indiana plant manager Matt Foster has used it to elevate production at the plant back to pre-COVID levels. He and his team recently closed with the highest output month since 2019.

“It’s been a journey over the last a couple of years to reinvent the plant,” he said. “We’ve built a good team; there has been a huge momentum shift for us to run the right products, and to keep pushing forward.

“We have new automotive customers, new upgrades, and we have been tasked with doing some very new products.”

Foster has worked at the plant for 26 years, the last four as its manager; he has seen what it takes to be successful. He also knows that it is not just one group but rather playing to the advantages of the campus to succeed.

Credit on the Fort Wayne campus is spread wide thanks to vertical integration.

Our Fort Wayne, Indiana facility.

Before a machine runs a single line in the facility, there is Disruptive Technology being developed at the MagForceX® Innovation Center through partnerships with customers and R&D teams. There is also testing and reformulations of enamels happening in the Chemical Processing plant, and new ways of forming the drawing tools and dies on-site at the Central Die Shop. Senior leaders also work directly with sales and production to scale quickly.

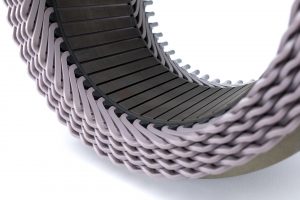

Signature products like EnduroTemp® 260+ and HVWW® are revolutionizing the electric vehicle market. Additional automotive projects for OEMs and Tier 1 suppliers are being developed and implemented at the plant which ultimately continues shaping how the world moves.

These cutting-edge projects are improving efficiency in traction motor production as well as improving the environmental impact on the automotive and transportation market.

While Essex Furukawa has its own Vision 2030 program to promote a sustainable future and reduce its carbon footprint, so do our automotive customers. We are proud to be a part of their supply chain and ultimately part of revolutionizing the automotive market with the exponentially growing EV market which aims to lessen the reliance on fossil fuels, reduce carbon emissions and impact on the planet.

Best practices are also being made more rapidly and being spread more readily.

“A highly critical part of our growth is the information sharing and the support of the engineering and technology group, globally,” Foster said. “We have made so many samples in the last couple of years that have really put us ahead of the learning curve and in our ability to understand some of the new products that we’re producing here and what our customers want produced here.”

Many of those new products are automotive in nature.

It is expected that by 2030 that there will be more than 31 million EVs on the road as well as 300 new models of electric vehicles available around the world.

HVWW® is helping to revolutionize electric vehicles.

That growth, leadership, vertical integration, as well as our footprint beyond Fort Wayne, allows Essex Furukawa to be uniquely positioned to partner locally and support our global customers. Through those local partnerships our team is able to deliver robust and reliable products that drive the performance and efficiency of the next generation of vehicles.

“The kind of automotive business that we support in this plant is such an incentive to everyone,” Foster said. “The decisions to trust us, to trust we are going to execute well—I’m appreciative. I’ve always been the proponent to bring it here, bring it on.”

With the increase in workload has come an increase in creativity. Many of the buildings on the campus are nearing a century in operation. There is a finite amount of floorspace in which to work and each iteration of technology can come with a new plant layout.

Foster regularly works in conjunction with North American President Jared Rowntree; VP Technology and Customer Care, Greg Caudill; VP of Operations, Kevin Park; as well as Director of Materials, Ben Crawford, to maximize the space for efficiency and production.

Depending on the project a floor configuration can happen in short order. Foster detailed that the projects often require major changes to oven and product placements for what is being worked on in Fort Wayne. He added that products that are in one spot on a Monday walkthrough are being shifted as quickly as a Thursday to reimagine what workflow looks like. That the ability to adapt and evolve quickly only makes turnaround times better for customers.

He also credited a direct line with North American VP of Sales, Andrew Winkeljohn for the boost.

“I believe our team earned the trust factor, across the company,” Foster said. “When any of us meet with leadership, and I tell them that the Fort Wayne team can support them, they know it will happen. And in the last couple months that has really been a game changer for the plant and everyone who works here.”

Foster also believes that this is the beginning of the story and not the end.

“More,” he said. “My next message is ‘Give us more.’”

It is a request he is likely to see materialize as he is expecting the Fort Wayne plant to push for regularly eclipsing 3-million-pounds per month.

For more information on our advances connect with an Essex Furukawa Magnet Wire representative.